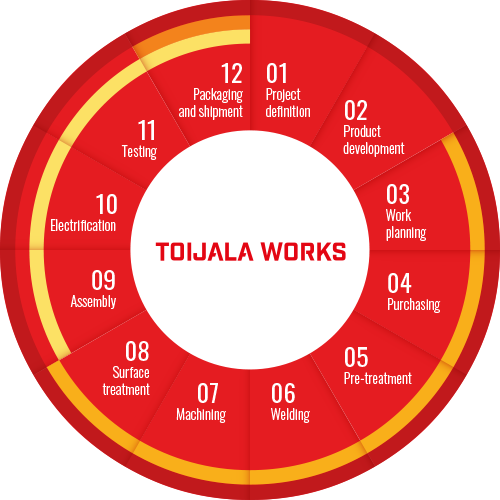

Total deliveries cover the different phases of manufacturing from idea to end product. Concentrating these phases under the same roof makes it possible to achieve a cost-efficient, high-quality result. Total deliveries may concern the serial production of machinery and equipment, or the manufacture of a prototype of a new product, developed together from the start.

The process starts with project definition, at which time budgets and timetables are drawn up for the various process phases. After defining the guidelines, the next step is the engineering and development phase: developing the product, scheduling the work, organizing and implementing subcontracts. We utilize our cooperation network for pretreatment, logistics, and the purchasing of components domestically and abroad.

Our own experts take care of welding, machining, surface treatment and installation. Our versatile skills include MIG/MAG welding, submerged arc welding, TIG welding, robot welding and various stages of machining. Submerged arc welding and wet painting are also among our strengths. Assembly is usually followed by electrification and machine control input, after which the machine is tested. Finally, it is ready for shipment and end use.

We also offer partial deliveries to the extent required. In this case, customers may choose particular process phases where they wish to use our services. These phases may concern, for example, only the manufacture of individual steel frames of the machines – in which case the process will not include machine assembly or testing – or, alternatively, only the final assembly and testing, in which case we will not be involved in the earlier stages of manufacturing.

How can we help you? Submit a message with your contact details and we will get back to you.